Roofing Services / Projects

LICENSED & BONDED

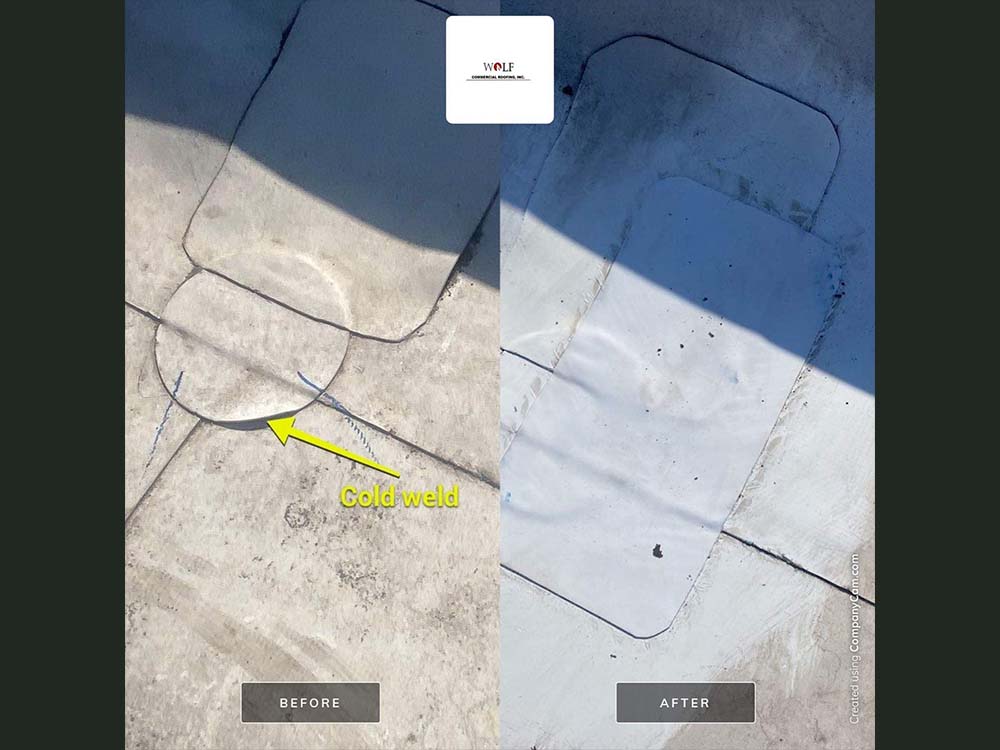

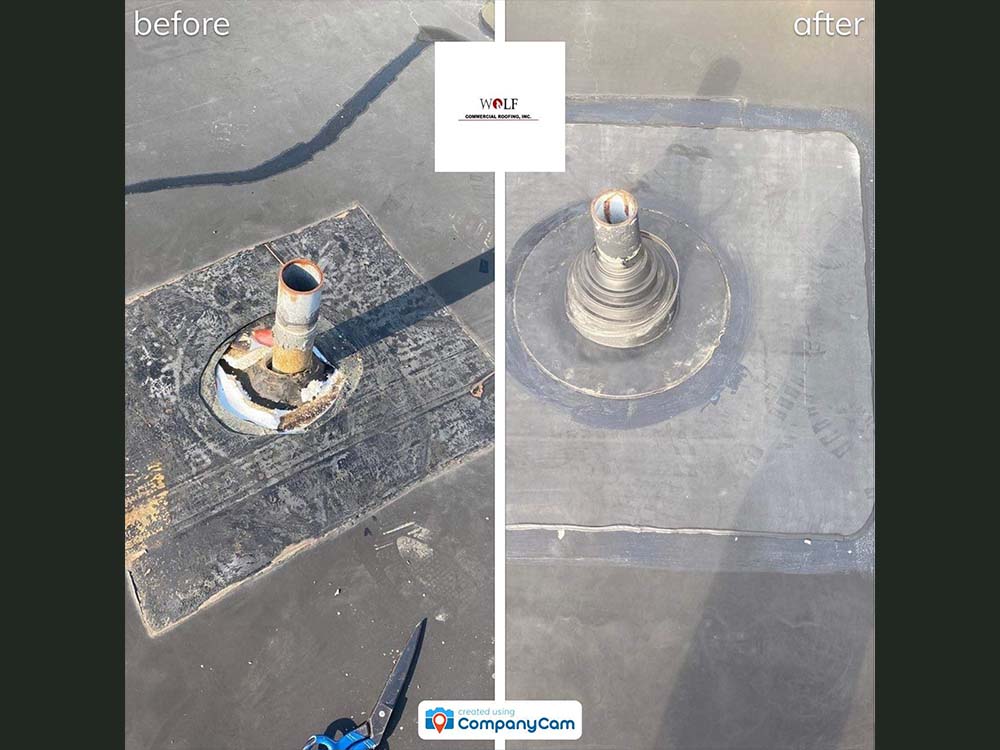

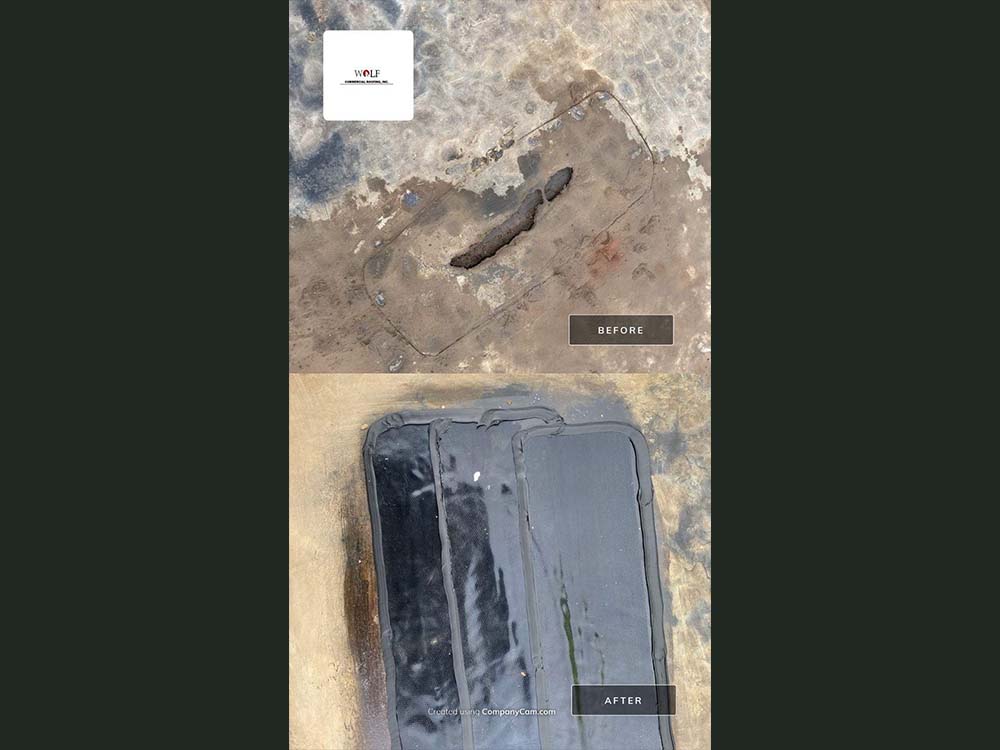

We offer a wide range of Commercial Roofing Services: Roof Inspections, Budgetary Proposals, Full Roof System Replacements, Temporary and Long-Term Repairs and a Prompt Service Department to handle any Emergency Leak or simple curb or pipe vent flashing!

© 2024 WOLF COMMERCIAL ROOFING, INC. | INDIANA | ALL RIGHTS RESERVED.